The global Brushless DC Motor Market Size is expected

to reach USD 17.6 billion by 2028 from USD 12.1 billion in 2023 at a CAGR of 7.9%

during the 2023-2028 period according to a new report by MarketsandMarkets™.

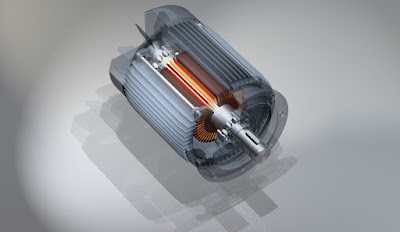

Brushless DC motors are synchronous electric motors that are driven by direct

current (DC). They are also known as electronically commutated motors (EC

motors). These motors are highly efficient in producing a large amount of

torque over broad speed ranges. In brushless DC motors, permanent magnets

rotate around fixed armatures, thereby overcoming the problem of connecting

current to armatures. Brushless DC motors are used in various applications

owing to their compactness, lightweight, and low maintenance requirements.

The increasing adoption of Brushless DC motors

is driven by their precise speed control, low maintenance requirements, and

high efficiency. Brushless DC motors offer enhanced reliability, reduced

electromagnetic interference, and compact designs, making them essential in

applications where these attributes are critical, such as in medical devices,

aerospace, and automation equipment.

Download PDF

Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=23539809

By Type

Segmentation

Based on

type, the Brushless DC Motor Market has been segmented into inner rotor and

outer rotor. Inner rotor brushless DC motor are in high demand across a wide

range of sectors due to its compact design, higher power density, and superior

efficiency. Inner rotor motors offer faster response times and better heat

dissipation, making them ideal for applications where space and weight are

critical factors. Additionally, the inner rotor design allows for a direct

connection to the load, enhancing overall system efficiency and performance,

which contributes to its dominant market share.

By

End Use Application Segmentation

This

report segments the Brushless DC Motor Market based on end user into consumer

electronics, automotive, manufacturing, medical devices, and others. Others

include HVAC, agricultural, solar pumps, and aerospace & defence

applications. The consumer electronics segment is expected to be the second fastest-growing

segment during the forecast period due to the increasing demand for

energy-efficient and compact solutions in devices like smartphones, laptops,

and household appliances. Brushless DC motors offer precise control, longer

lifespan, and reduced noise, making them well-suited for applications in

consumer electronics. As technology evolves and consumers prioritize

high-performance and energy-efficient gadgets, the demand for brushless DC

motors in this segment continues to surge, contributing to its rapid growth.

Request

Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=23539809

Regional

Analysis

North

America is expected to be the second-largest Brushless DC Motor Market during

the forecast period. The North America region has been subdivided into three

key countries: US, Canada and Mexico. The regio n's

emphasis on automation in industries, such as manufacturing and healthcare, is

driving the demand for efficient and reliable brushless DC motors.

Additionally, the rising awareness of environmental sustainability has fueled

the growth of electric vehicles, further boosting the demand for these motors. Favorable

government initiatives and investments in renewable energy projects are also

contributing to the region's prominence in the Brushless DC Motor Market.

Key

Players

Some of the major players in the Brushless DC Motor Market are Ametek Inc. (US), Allied Motion, Inc. (US), NIDEC Corporation (Japan), MinebeaMitsumi Inc. (Japan), and Johnson Electric Holdings Limited (China).